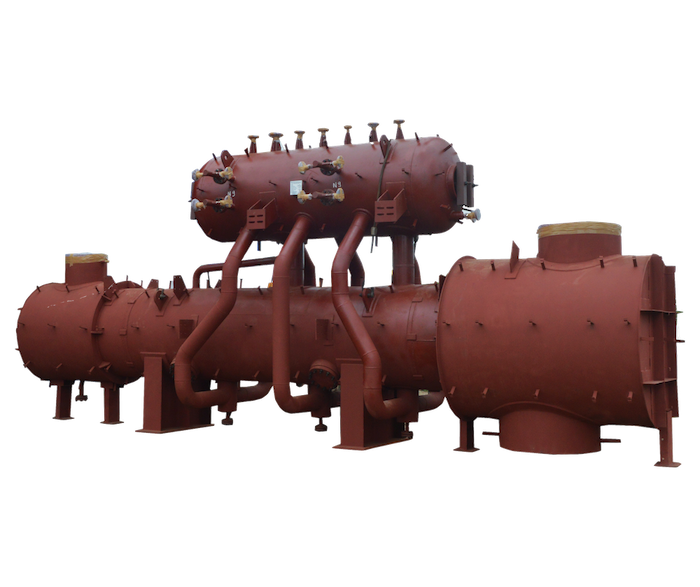

Waste Heat Recovery Boiler

We have been recently Certified by Engineers India Limited ( EIL) for the Shell & Tube Waste Heat Recovery Boilers

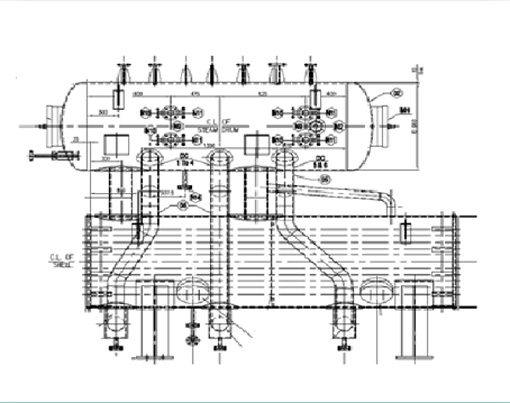

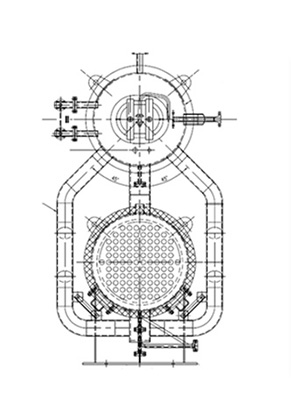

WHRB are fire tube industrial boilers equipped with advanced instrumentation to deliver maximum possible heat recovery.

These boilers are ideal to recover heat from flue Gas, incinerators, blast furnace exhausts etc. They enhance the system efficiency and help save fuel and money.

Waste Heat Recovery Boilers are designed for easy inspection and maintenance.

Trust Well Engineers (India) Pvt. Ltd. has executed several

Prestigious boiler projects.

Key Features :

- We are Enlisted company by Engineers India Limited (EIL) & IBR for the Waste Heat Recovery Boilers manufacturing.

- Our WHRBs are suitable for Waste Flue Gases from furnace, incinerator exhaust gas from steel industries and any type of flue gases having temperature above 500 ̊c

- The Payback period of Waste Heat Recovery Boiler is less than 1 Year.

- Tailor made design to suit customer requirements.

- Complete Shop built Assembly (For fire tube boiler) which reduces site work.

- WHRB design & manufacturing for variety of complex and exotic high-sulfur exhaust gases.

- A Specially Designed Knuckle Tube Sheet is utilized to prevent tube-to-tube sheet joint failures.

- To avoid the formation of steam blanket near to the front Tube sheet, we've incorporated specially designed system.

- Design suitable for Liquid Waste firing directly in boiler instead of incinerator route.

- All statutory/ Govt. IBR requirements are taken care by us.

- Orbital welding and fluorescent DP testing are fundamental competencies essential for ensuring best quality. Highly Robust Construction.