What is Soot Blower? And The Role of Soot Blowers in Industrial Operations

The development of soot is one such boiler problem. As a result of combustion, soot is a carbon-based substance that builds up and sticks to the surfaces and walls of the steam boiler system while it is in use.

What is Soot :

What is Soot Blower :

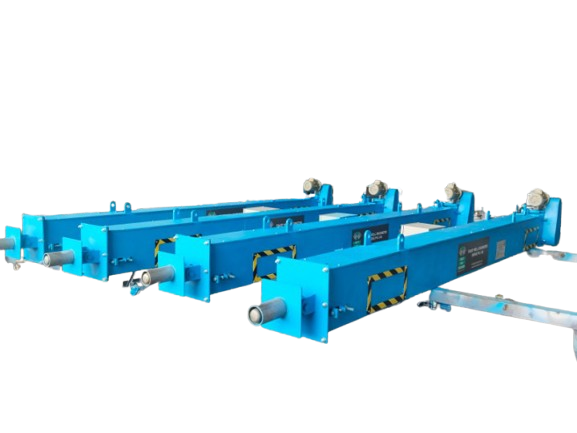

A soot blower is a mechanical device used in industrial settings, particularly in boilers, furnaces, and steam generators, to remove accumulated soot or ash deposits from surfaces within the equipment. If these deposits are not removed, they may reduce overall performance, reduce the effectiveness of heat transfer, and perhaps cause device failure or damage.

The role of soot blowers in industrial operations is crucial for maintaining optimal performance and efficiency. The following is how they help:

- Enhanced Efficiency: Soot blowers help to maintain clean surfaces within boilers and furnaces, ensuring efficient heat transfer. By removing soot and ash deposits, they prevent the buildup of insulating layers that can reduce thermal efficiency and increase fuel consumption.

- Preventing Equipment Damage: Buildup of ash and soot can cause surfaces on equipment to break down and dissolve. By routinely cleaning these surfaces, soot blowers reduce this risk, increasing the life of industrial equipment and lowering maintenance expenses.

- Enhancement of Safety: By lowering the possibility of overheating and potential equipment breakdowns, clean equipment surfaces encourage safer operating conditions. This is especially crucial for sectors like power plants where worker safety is a top priority.

- Optimized Performance: By preventing the buildup of soot and ash deposits, soot blowers contribute to the consistent and reliable performance of industrial equipment. This is essential for maintaining productivity and meeting production targets in various industrial processes.